Manufacturing

Optical Manufacturing

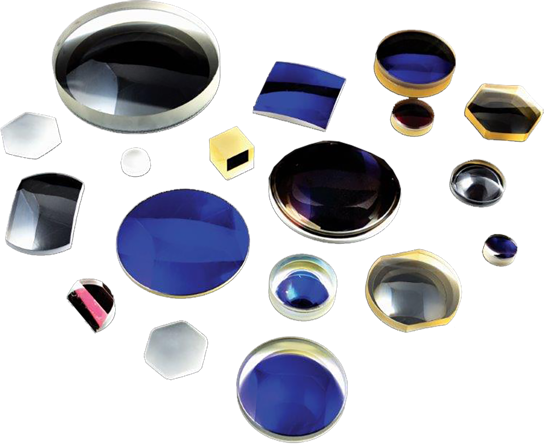

In the optical production department, grinding, polishing, centering and measuring processes are carried out by both manual and CNC machines. The measurement processes are carried out with very sensitive interferometers and profilometers.

In optical production;

- Processing up to 5 mm 150 mm diameter

- Processing in 5 mm Infinite Radius intervals

- Measuring in 5 mm Infinite Radius intervals

- Concave convex and plano visible lens production

- Window filter and prism production

- Spherical visible zone lens production

- Aspherical visible lens production

- Spherical and a spherical infrared zone production

- Production of polycarbonate lenses by plastic injection method

- Diffractive infrared region lenses

- In laser optics production can be performed with a surface roughness

of 0 2 fringe λ 10 and a surface quality of 20/10 - Ultraviolet ( visible ( and near infrared ( SWIR) AR, HR,

band pass filter short pass filter and long pass filter can be produced - Laser optical thin film coatings are produced

- We have all kinds of optical glass fused silica zerodur processing

capability

Optical Thin Film Coating

Optical thin film coating processes are carried out with PVD technology in class 1000 clean room conditions.

- Transmission T>99 %

- Reflection R>98,0 %

- Wavelenght 200nm < λ < 3000nm

- Optical cementing

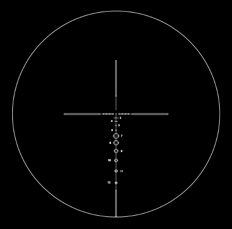

Reticle Printing

Reticle printing is performed on the surface of prisms by means of masklessphotolithography. Our maskless photolithography device has a resolution of 0.6microns and is capable of processing 28 prisms at a time.

The processing of a single prism can be completed in as little as 15 seconds.

Mechanical Production

Aselsan Sivas has a capability to manifacture the precise optomechanical products with a great efficiency and cost effectiveness. Optomechanical production starts with the manufacturing analysis of the mechanical parts. After that, the manufacturing steps are defined. According to manufacturing steps, the precise machining is accomplished.

All optomechanic manufacturing is done with 4 axis and 5 axis vertical and horizontal machining centers. The finished parts are controlled with CMM devices according to the tolerances described in design documents

- Aluminium precision casting mechanical parts

- Ocular, collimator, objective optomechanical parts

- Continuous zoom objective optomechanical parts with helical slots

- Delrin, polyamide, peek, brass, aluminium, stainless steel and titanium optomechanical manufacturing

Assembly and Testing

Aselsan Sivas Assembly unit, the production of sub-tools is made first. The sub-assemblies that are completed are brought to the device level, subjected to system tests and environmental conditions tests and turned into products.

AS9100 Space Aviation and ISO 9001 Quality Management System standards are applied at all stages until the materials are approved by the input quality unit and then packaged as products.